Plain Dutch Woven Mesh

Plain Dutch Woven Mesh

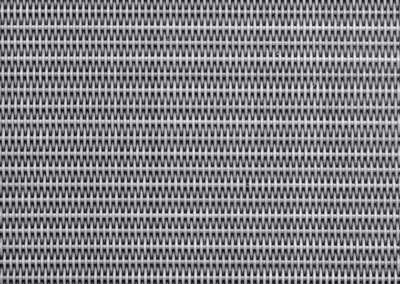

The pattern of the plain Dutch woven mesh is the same as the plain square weave, but the weft yarns are smaller in diameter than the warp yarns.

The wires are intertwined closely together resulting in a small triangular opening. This fabric produces a strong fabric with a small open area and greater resistance with a good flow rate so that it is suitable for high pressure filtration. The shapes and position of the openings help to retain particles and increase the formation of the filter cake.

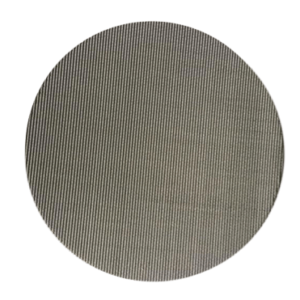

Plain Dutch woven mesh is most often used for high pressure filtration processor to separate itself from other media in spaceflight, petroleum, chemical industry, etc.

CHARACTERISTICS OF THE PLAIN FABRIC:

Each warp wire and each weft wire passes over and under the next adjacent complementary wire. Same as normal plain weave, except warp wires have a larger diameter than weft wires. This allows for a greater number of meshes in the weft direction.

Features: “zero” aperture, more solid than Plain square woven mesh, relatively high open area, suitable for all kinds of filtration.

PRODUCT FEATURE

| Tissue | Mesh | Wire diameter (inches) | Opening (inches) | Open rate | Weight (kg / m2) |

|---|---|---|---|---|---|

| smooth | 8x20 | 2,44X0,98 | 13-13,7 | 0.64 | 0.52 |

| smooth | 12x64 | 0,022x0,015 | 11,811 | 0.58 | 0.42 |

| smooth | 14x88 | 0,019x0,012 | 11-11,5 | 0.48 | 0.3 |

| smooth | 14x100 | 0,019x0,012 | 7,87 | 0.44 | 0.3 |

| smooth | 16x80 | 0,016x0,014 | 7,87-8,34 | 0.42 | 0.3 |

| smooth | 20x110 | 0,09x0,18 | 6,29 | 0.385 | 0.25 |

| smooth | 24x110 | 0,014x0,009 | 4,40-4.92 | 0.355 | 0.25 |

| smooth | 24x128 | 0,09x0,18 | 4,1-4.40 | 0.31 | 0.22 |

| smooth | 30x150 | 0,016x0,014 | 3,85-0.5 | 0.23 | 0.18 |

| smooth | 40x200 | 0,14x0,11 | 30,82-3,14 | 0.18 | 0.14 |

| smooth | 50x250 | 0,10x0,071 | 2,36-2,44 | 0.17 | 0.1 |

| smooth | 80x400 | 0,10x0,025 | 1,57-1,61 | 0.13 | 0.75 |